Plastic injection molding companies play a pivotal role in driving innovation across various industries. This manufacturing process, which involves injecting molten plastic into a mold to create parts and products, has become indispensable due to its efficiency, versatility, and ability to produce complex designs with precision. As the demand for high-quality and cost-effective products continues to grow, these companies are at the forefront of technological advancements that push the boundaries of what is possible.

One way plastic injection molding companies drive innovation is through material development. The industry is continually exploring new materials that offer enhanced properties such as increased strength, flexibility, or sustainability. Biodegradable plastics and composites made from renewable resources are becoming more prevalent as environmental concerns take center stage. These materials not only reduce the carbon footprint but also open up new possibilities for product design and functionality.

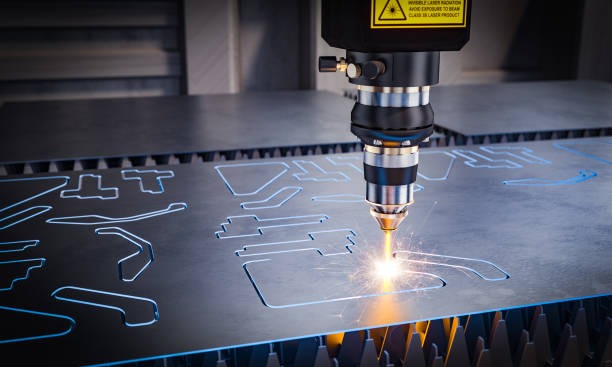

In addition to material innovation, advancements in technology have significantly impacted the injection molding process itself. Automation and robotics have streamlined production lines, increasing efficiency while reducing human error. Smart manufacturing systems equipped with sensors and data analytics provide real-time monitoring of operations, enabling manufacturers to optimize processes and improve quality control. This integration of Industry 4.0 technologies ensures that production is https://amt-mat.com/plastic-molding-injection-companies-shaping-the-future-of-manufacturing/ both efficient and adaptable to changing demands.

Furthermore, rapid prototyping techniques such as 3D printing complement traditional injection molding methods by allowing companies to quickly develop prototypes for testing before committing to large-scale production runs. This capability accelerates product development cycles and fosters an environment where experimentation leads to innovative solutions without significant financial risk.

Collaboration between plastic injection molding companies and other sectors also fuels innovation. By working closely with designers, engineers, and researchers from various fields such as automotive, healthcare, consumer electronics, or aerospace industries; these companies gain insights into specific needs that drive customized solutions tailored for particular applications.

Moreover, sustainability initiatives within this sector promote eco-friendly practices throughout all stages of production – from minimizing waste during fabrication processes down through recycling programs aimed at reusing scrap material effectively without compromising on quality standards set forth by clients worldwide who increasingly prioritize environmentally responsible sourcing decisions when selecting partners capable enough delivering results aligned their values too!

In conclusion: Plastic Injection Molding Companies continue shaping future innovations across diverse markets globally thanks largely due ongoing efforts towards improving existing technologies alongside developing entirely novel approaches addressing challenges faced today tomorrow alike!